Technology

Our research led approach has produced advanced technologies for performance in the harshest marine conditions. Through continuous material discovery and integration of recycled and bio-based components, Strike delivers technical excellence with a reduced environmental footprint.

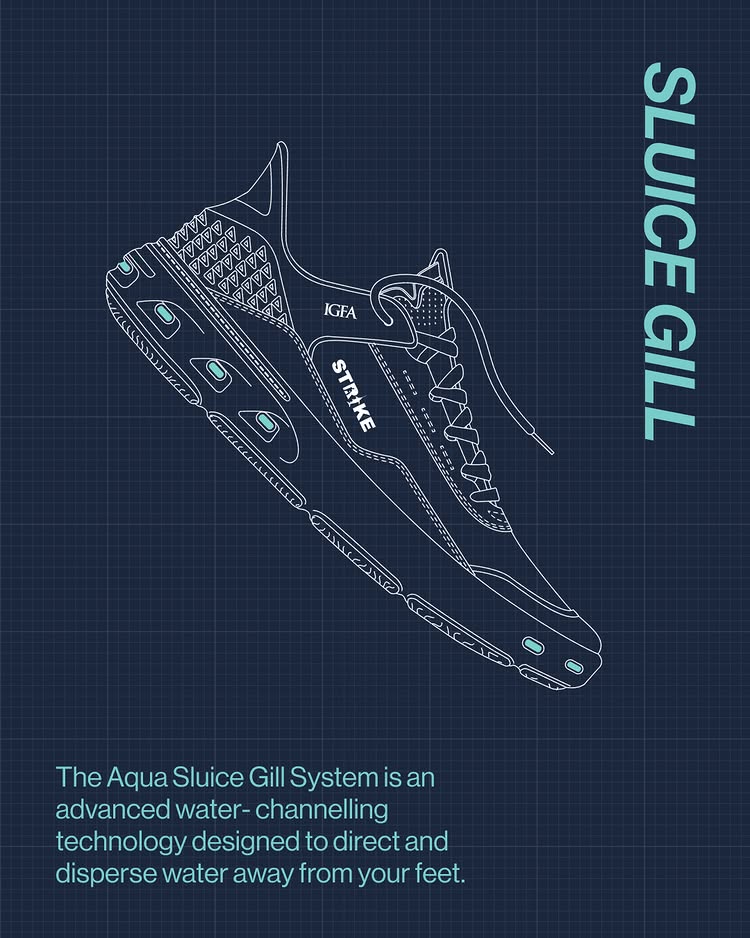

AQUA SLUICE GILL

The Aqua Sluice Gill System channels water away from the foot through engineered channels, promoting faster drying and greater comfort. This design maintains outsole durability and slip resistance, ensuring stability in wet, demanding conditions.

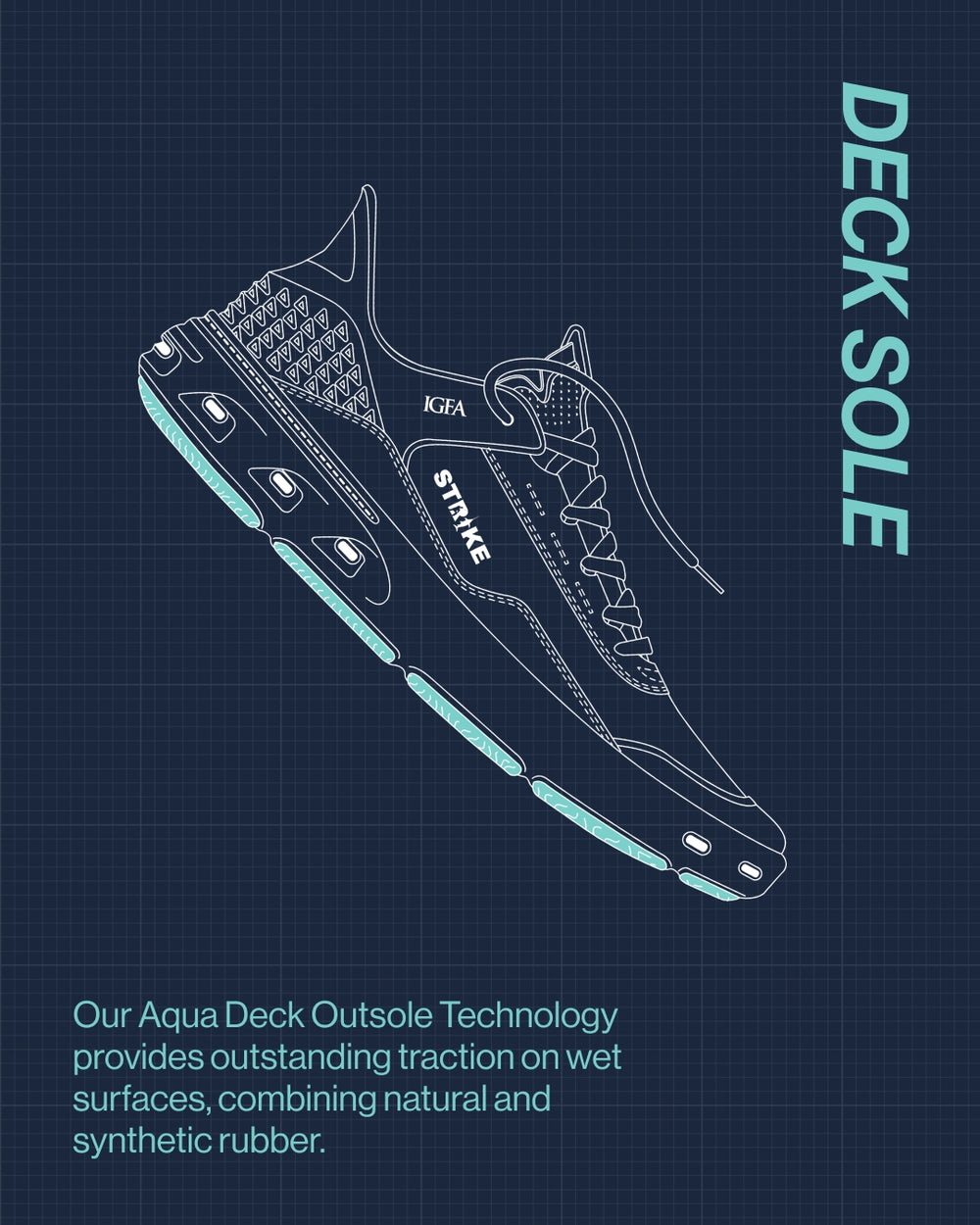

AQUA DECK SOLE

Our Aqua Deck Outsole Technology delivers superior ‘on-deck’ traction through an advanced compound formulation that integrates high-grade natural and synthetic rubber to deliver exceptional traction on wet, slippery surfaces.

The wet grip of our outsoles is significantly enhanced by special siped soles. These thin, razor-cut slits across the sole surface work to channel water away from the contact point, effectively creating a drier surface area between the shoe and the deck. This maximises surface adhesion in wet and slippery conditions.

SEAQUAL® YARN

Engineered for high performance in wet and variable environments, our footwear features textile made using SEAQUAL® YARN for exceptional durability and quick-drying qualities. This innovative yarn, developed through the SEAQUAL INITIATIVE, is composed of approximately 10% Upcycled Marine Plastic - collected and repurposed from marine litter - and 90% post-consumer recycled polyester. The SEAQUAL INITIATIVE is a global community working to combat marine plastic pollution by recovering ocean plastic and transforming it into high-quality, usable materials. Incorporating SEAQUAL® YARN reflects our commitment to marine ecosystem restoration, circular design and innovation in material development.

SOLUM™

Solum™ is a biomaterials innovator tackling the plastic crisis – the growing threat of plastic waste in our oceans and ecosystems, by redefining what we build with. Their 100% bio-based plant additive replaces toxic petrochemicals in our rubber outsole compound without compromising performance. Traditionally, outsoles rely on fossil-fuel-derived chemicals that harm the environment. Solum’s plant-based alternative uses renewable biological nutrients - the same ones that give trees and plants their strength and resilience. As they wear, Solum’s BioTread™ material gradually releases plant-based nutrients into the environment – helping support healthy soils and contributing to natural regeneration.

RECYCLED EVA AND rPET

We incorporate recycled EVA (Ethylene-Vinyl Acetate) in the footbed and midsole to reduce the need for virgin materials and lower the environmental impact of extraction and processing. Reusing EVA helps keep plastic waste out of landfills and oceans, while still delivering the cushioning and support needed. We also use recycled rPET, made from post-consumer plastic, to create lightweight and moisture-regulating material. This not only diverts plastic from the waste stream but also reduces our reliance on virgin polyester, helping cut down on emissions and resource use.